Supply Chain Logistics Optimization Techniques

Supply chain logistics optimization techniques are revolutionizing the way businesses operate, offering a wealth of benefits that can transform operations. From reduced costs to enhanced customer service, the potential for optimization is vast. Embark on a journey of discovery as we delve into the strategies and best practices that can empower your supply chain to soar.

Understanding the importance of optimizing supply chain logistics is crucial. By streamlining processes, businesses can unlock cost savings, improve customer satisfaction, and gain a competitive edge. Examples abound of companies that have successfully implemented optimization techniques, reaping the rewards of increased efficiency and profitability.

Introduction: Supply Chain Logistics Optimization Techniques

Supply chain logistics optimization techniques are strategies and methods employed to improve the efficiency, effectiveness, and overall performance of supply chain operations. By optimizing logistics processes, businesses can reduce costs, improve customer service, and gain a competitive advantage.

Optimizing supply chain logistics is crucial for businesses to stay competitive in today’s global marketplace. With complex supply chains and increasing customer demands, businesses need to find ways to streamline operations, reduce lead times, and improve visibility across the entire supply chain.

Types of Supply Chain Logistics Optimization Techniques

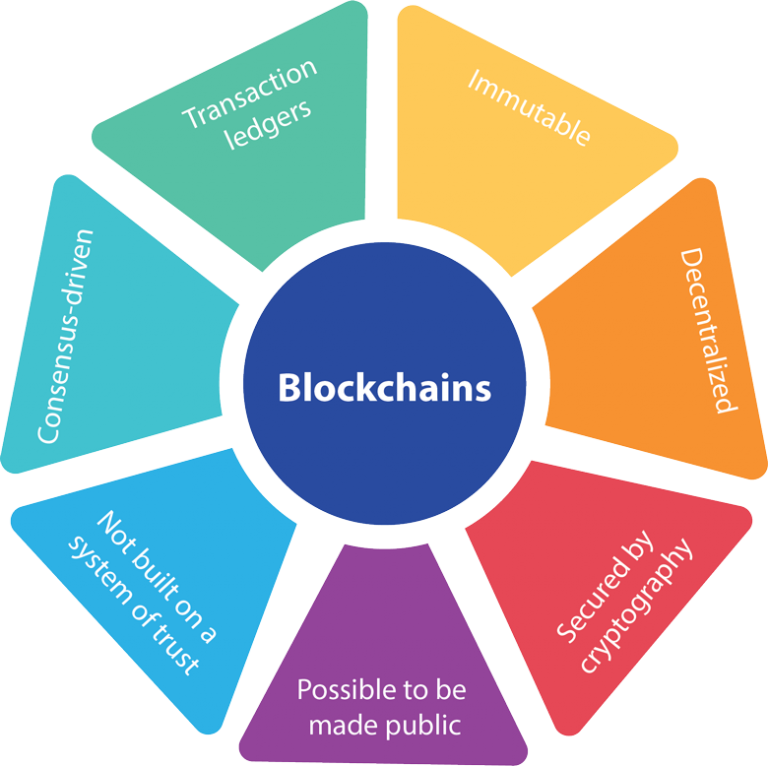

Supply chain logistics optimization techniques encompass a wide range of strategies and technologies designed to improve the efficiency, effectiveness, and profitability of supply chains. These techniques can be categorized into several key areas:

Inventory Management

Inventory management techniques aim to optimize the levels and flow of inventory throughout the supply chain. This involves determining the optimal inventory levels, managing inventory costs, and implementing strategies to minimize waste and spoilage. Effective inventory management can lead to reduced carrying costs, improved customer service, and increased inventory turnover.

Transportation Management

Transportation management techniques focus on optimizing the movement of goods from suppliers to customers. This includes selecting the most efficient transportation modes, optimizing routing and scheduling, and managing freight costs. Effective transportation management can reduce shipping costs, improve delivery times, and enhance supply chain visibility.

Warehousing Management

Warehousing management techniques aim to optimize the storage and handling of goods in warehouses. This involves designing efficient warehouse layouts, implementing inventory management systems, and utilizing technology to automate warehouse operations. Effective warehousing management can improve space utilization, reduce labor costs, and enhance inventory accuracy.

Order Fulfillment

Order fulfillment techniques focus on optimizing the process of receiving, processing, and shipping customer orders. This involves implementing efficient order management systems, automating order picking and packing processes, and managing order tracking and delivery. Effective order fulfillment can improve order accuracy, reduce fulfillment times, and enhance customer satisfaction.

Benefits of Supply Chain Logistics Optimization

Optimizing supply chain logistics offers numerous benefits that can significantly enhance a company’s operations and overall performance.

By implementing effective optimization techniques, businesses can reap the rewards of:

Reduced Costs

- Lower inventory holding costs through improved inventory management and forecasting.

- Reduced transportation expenses by optimizing routes, consolidating shipments, and negotiating better rates.

- Lower labor costs due to increased efficiency and automation.

Improved Customer Service

- Faster delivery times and increased order accuracy, leading to higher customer satisfaction.

- Improved responsiveness to customer inquiries and complaints.

- Enhanced visibility into the supply chain, allowing for proactive problem-solving and communication.

Increased Efficiency

- Streamlined processes and reduced waste through automation and technology.

- Improved coordination and collaboration among supply chain partners.

- Increased capacity and flexibility to meet changing demand.

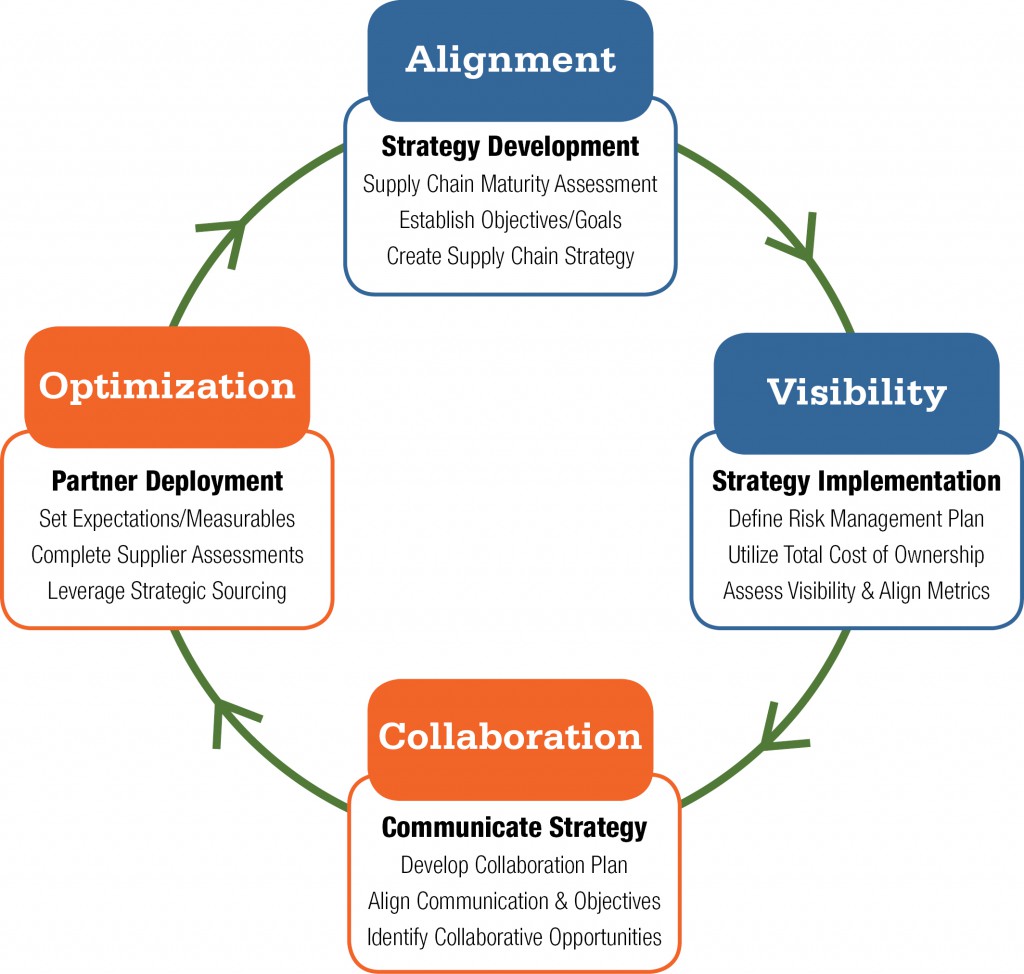

Enhanced Visibility

- Real-time visibility into inventory levels, order status, and transportation movements.

- Improved communication and information sharing among supply chain stakeholders.

- Enhanced ability to track and monitor key performance indicators.

Challenges of Supply Chain Logistics Optimization

Optimizing supply chain logistics is a complex task that comes with its own set of challenges. These challenges can stem from various factors, including the complexity of supply chains, lack of data, and changing customer demands.

One of the primary challenges in supply chain logistics optimization is the complexity of supply chains themselves. Modern supply chains are often global in scope, involving multiple tiers of suppliers, manufacturers, distributors, and customers. This complexity makes it difficult to coordinate and optimize the flow of goods and information throughout the supply chain.

Lack of Data

Another challenge in supply chain logistics optimization is the lack of data. Many companies lack the data they need to make informed decisions about how to optimize their supply chains. This can be due to a lack of data collection, poor data quality, or difficulty in accessing data from different parts of the supply chain.

Changing Customer Demands

Finally, supply chain logistics optimization is also challenged by changing customer demands. Customers are increasingly demanding faster, cheaper, and more customized products and services. This puts pressure on supply chains to become more agile and responsive, which can be difficult to achieve.

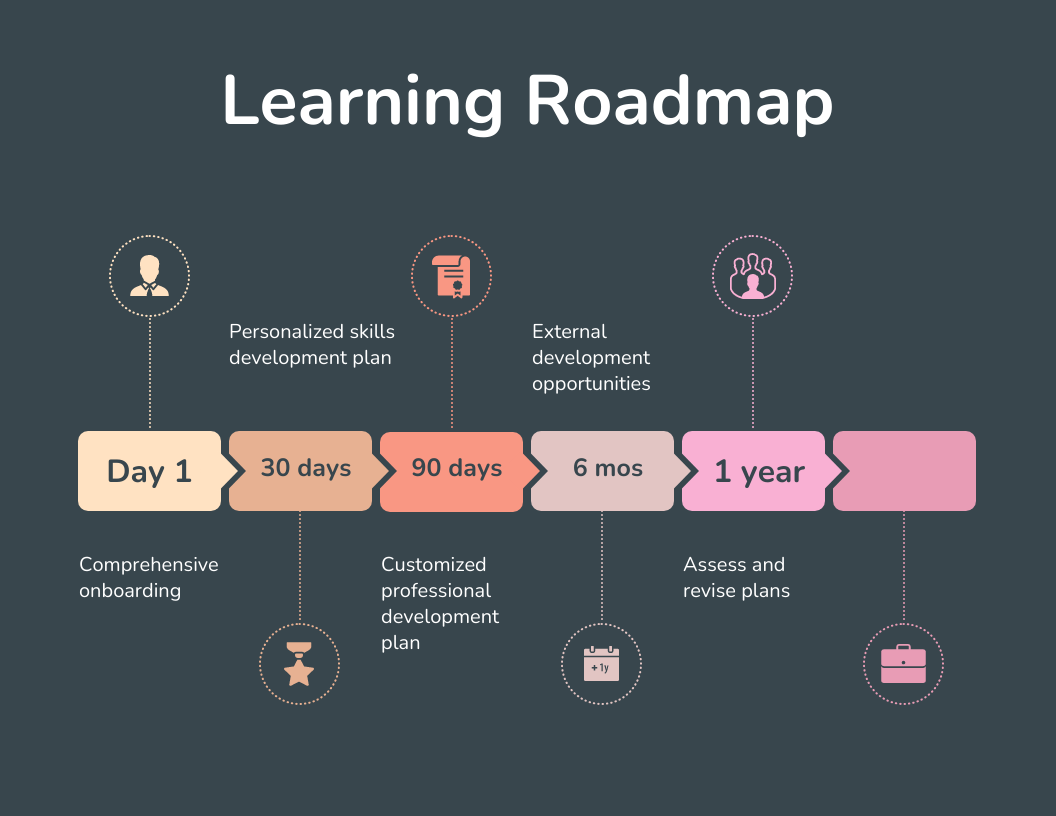

Best Practices for Supply Chain Logistics Optimization

Supply chain logistics optimization is a crucial aspect of ensuring efficient and cost-effective operations. By implementing best practices, organizations can streamline processes, reduce costs, and enhance customer satisfaction.

Use Technology to Automate Processes

Leveraging technology to automate repetitive and manual tasks can significantly improve efficiency. Implementing inventory management systems, automated data collection, and predictive analytics can reduce errors, increase accuracy, and provide real-time visibility into supply chain operations.

Collaborate with Suppliers and Customers

Collaboration with suppliers and customers fosters transparency and strengthens relationships. By sharing data, aligning forecasts, and jointly developing solutions, organizations can improve supply chain resilience, reduce lead times, and enhance overall coordination.

Monitor and Measure Performance

Establishing performance metrics and regularly monitoring key indicators is essential for evaluating the effectiveness of optimization efforts. Tracking metrics such as inventory turnover, order fulfillment rates, and customer satisfaction can identify areas for improvement and drive continuous optimization.

Case Studies of Supply Chain Logistics Optimization

Many businesses have successfully optimized their supply chain logistics, leading to improved efficiency, cost reduction, and enhanced customer satisfaction.

Amazon

Amazon has been a pioneer in supply chain logistics optimization. By implementing advanced technologies such as artificial intelligence, machine learning, and robotics, Amazon has automated many aspects of its supply chain, including inventory management, order fulfillment, and transportation. This has resulted in faster delivery times, reduced costs, and improved inventory accuracy.

Walmart

Walmart has also made significant investments in supply chain logistics optimization. The company has implemented a number of initiatives, including cross-docking, vendor-managed inventory, and RFID technology. These initiatives have helped Walmart to reduce inventory levels, improve product availability, and increase supply chain visibility.

Nike, Supply chain logistics optimization techniques

Nike has focused on optimizing its supply chain logistics to meet the demands of its global customer base. The company has implemented a number of initiatives, including lean manufacturing, demand forecasting, and collaborative planning. These initiatives have helped Nike to reduce lead times, improve product quality, and increase customer satisfaction.

Essential Questionnaire

What are the key benefits of supply chain logistics optimization?

Optimization can lead to reduced costs, improved customer service, increased efficiency, and enhanced visibility.

What are some common challenges in optimizing supply chain logistics?

Challenges include the complexity of supply chains, lack of data, and changing customer demands.

What are some best practices for optimizing supply chain logistics?

Best practices include using technology to automate processes, collaborating with suppliers and customers, and monitoring and measuring performance.