Supply Chain Optimization Techniques

In today’s dynamic business landscape, Supply chain optimization techniques are the key to unlocking efficiency, reducing costs, and enhancing customer satisfaction. Join us as we delve into the strategies and technologies that are revolutionizing supply chain management.

From inventory management to data analytics, this comprehensive guide will empower you to optimize your supply chain for greater agility, resilience, and profitability.

Inventory Management Techniques

Inventory management is crucial for supply chain optimization, ensuring the right products are available at the right time and place. Effective inventory management techniques minimize costs, reduce waste, and improve customer satisfaction.

Just-in-Time (JIT)

JIT aims to reduce inventory levels by producing or acquiring goods only when needed. This minimizes storage costs, frees up capital, and improves product freshness.

Vendor-Managed Inventory (VMI), Supply chain optimization techniques

VMI involves partnering with suppliers to manage inventory levels. Suppliers monitor demand, replenish stock, and optimize inventory levels, ensuring availability while reducing overstocking or shortages.

Benefits of Inventory Management Techniques

- Reduced inventory costs

- Improved cash flow

- Enhanced customer satisfaction

- Increased efficiency and productivity

Challenges of Implementing Inventory Management Techniques

- Accurate demand forecasting

- Supplier reliability

- Technology integration

- Employee training

Transportation and Logistics Optimization: Supply Chain Optimization Techniques

Transportation and logistics play a critical role in optimizing supply chains by ensuring the efficient and cost-effective movement of goods from suppliers to customers. Optimizing these processes can lead to reduced lead times, lower transportation costs, and improved customer satisfaction.

Route Planning

Effective route planning is essential for optimizing transportation efficiency. This involves determining the most efficient routes for vehicles, taking into account factors such as traffic patterns, road conditions, and delivery time constraints. Advanced routing software can help businesses optimize routes, reducing travel time and fuel consumption.

Mode Selection

Choosing the appropriate mode of transportation is crucial for optimizing logistics costs and delivery times. Factors to consider include the type of goods being shipped, the distance, and the desired delivery speed. Intermodal transportation, which combines different modes of transport, can offer cost and time savings.

Technology Impact

Technology has revolutionized transportation and logistics optimization. Telematics systems provide real-time visibility into vehicle locations and performance, enabling businesses to track shipments and optimize routes in real-time. Additionally, blockchain technology can enhance transparency and security in supply chains, reducing delays and inefficiencies.

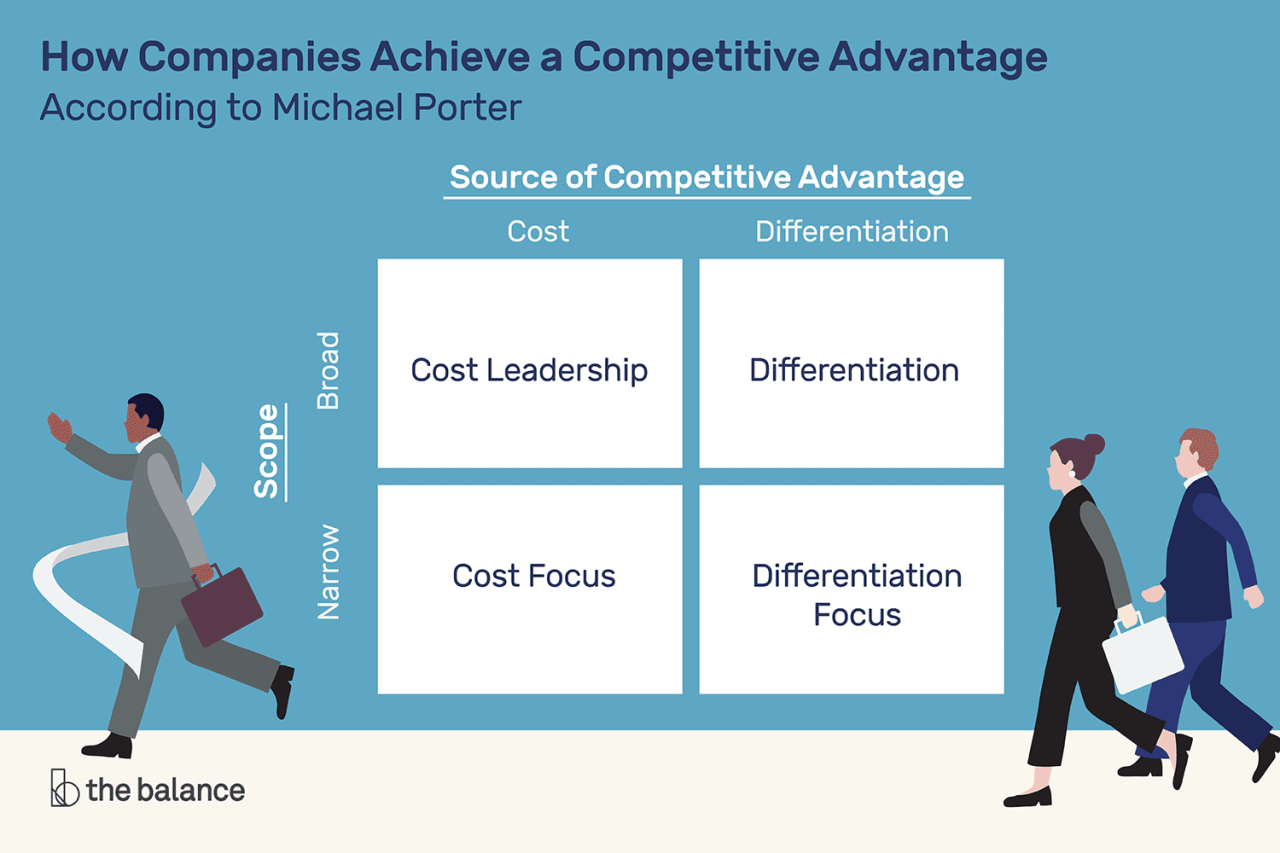

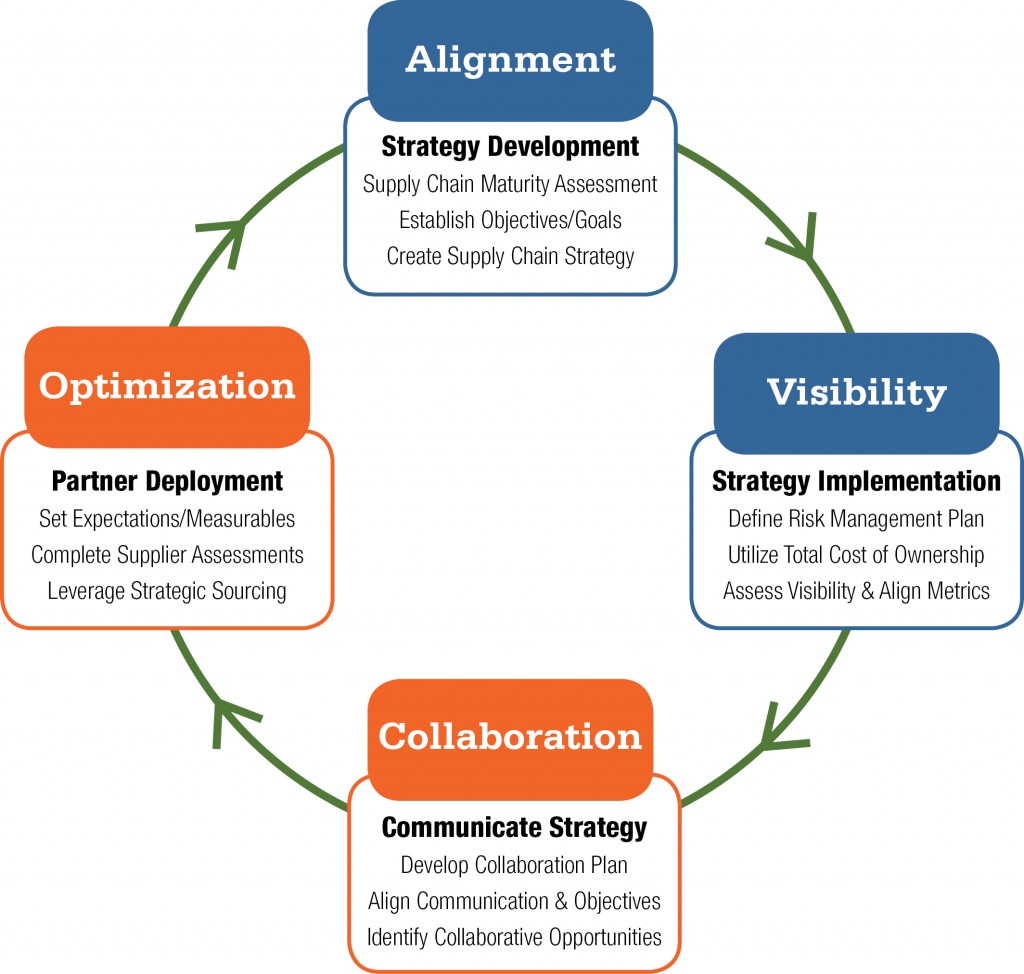

Supplier Relationship Management

Supplier relationship management (SRM) is a critical component of supply chain optimization. It involves managing and fostering relationships with suppliers to ensure a reliable and efficient supply chain. Effective SRM can lead to reduced costs, improved quality, and increased innovation.

There are several strategies for building and maintaining strong supplier relationships. These include:

- Establishing clear communication channels and expectations

- Developing collaborative relationships based on trust and mutual respect

- Providing regular feedback and support to suppliers

- Involving suppliers in product development and innovation

Technology in Supplier Relationship Management

Technology can play a significant role in supplier relationship management. SRM software can help businesses track and manage supplier performance, automate communication, and facilitate collaboration. This can lead to improved efficiency and effectiveness in SRM.

Data Analytics and Forecasting

Data analytics and forecasting play a crucial role in supply chain optimization by providing valuable insights into historical data and predicting future trends. Through data analysis, businesses can identify patterns, correlations, and anomalies within their supply chain operations, enabling them to make informed decisions and improve efficiency.

Forecasting Techniques

Forecasting is an essential aspect of supply chain optimization, as it helps businesses anticipate future demand and plan accordingly. Various forecasting techniques are employed, including:

– Time Series Analysis: This technique analyzes historical data to identify patterns and trends, allowing for predictions of future demand.

– Regression Analysis: This statistical method establishes relationships between independent and dependent variables, enabling the prediction of demand based on factors such as economic indicators or market trends.

– Machine Learning Algorithms: Advanced algorithms, such as neural networks and decision trees, can be trained on historical data to make accurate predictions, even in complex and non-linear scenarios.

By leveraging data analytics and forecasting, businesses can optimize their supply chain operations, reduce inventory waste, improve customer service, and gain a competitive advantage in the market.

Technology and Innovation

Technology has revolutionized the supply chain industry, enabling businesses to optimize their operations, reduce costs, and improve customer service. Emerging technologies such as artificial intelligence (AI), blockchain, and the Internet of Things (IoT) are transforming the way supply chains are managed.

AI in Supply Chain Optimization

- Predictive analytics to forecast demand, optimize inventory levels, and improve decision-making.

- Automated processes to streamline tasks, reduce errors, and free up resources for more strategic initiatives.

- Chatbots to provide customer support, answer queries, and improve communication.

Blockchain for Secure and Transparent Supply Chains

- Creates a secure and tamper-proof record of transactions, enhancing trust and transparency.

- Improves traceability, allowing businesses to track products from origin to delivery.

- Reduces fraud and counterfeiting, protecting consumers and brand reputation.

IoT for Real-Time Visibility and Control

- Connects devices and sensors to provide real-time data on inventory levels, equipment performance, and transportation status.

- Enables proactive monitoring and predictive maintenance, reducing downtime and improving asset utilization.

- Facilitates collaboration and coordination among different stakeholders in the supply chain.

Question & Answer Hub

What are the benefits of inventory management techniques?

Inventory management techniques can reduce costs, improve customer service, and increase profitability by optimizing inventory levels and minimizing waste.

How can I improve transportation and logistics efficiency?

Optimizing transportation and logistics involves route planning, mode selection, and leveraging technology to reduce transit times, minimize costs, and improve reliability.

Why is supplier relationship management important in supply chain optimization?

Strong supplier relationships ensure reliable deliveries, competitive pricing, and access to innovative products and services.